WSHE BULLETIN

July 2022

Issue #54

HSB launched our very first Innovation & Productivity Award to encourage inter-departments, projects sites and individual including workers to explore and come up with innovative, efficient methodology to enhance productivity. These include reviewing/ redesigning workflow and processes from planning, design, construction development to safety and streamlining routine tasks such as administrative aspects.

Innovation is vital in the organisation because it allows us to stay relevant in this competitive construction industry and hence, HSB Innovation & Productivity Award will be one of our annual events to inculcate the importance of continual improvements. Selected proposal and solutions will be shared and implemented in our projects/ offices where possible.

The committee had received a total of 26 innovative submissions from group and individual category with topics relating to new construction methodology to boost efficiency, improvement to existing work sequences to enhance productivity, EHS related proposals to improve workers safety on sites and the use of technology to speed up time taken for tracking and monitoring etc. The panel of judges had shortlisted the submissions and after rounds of evaluations and presentations by the participants, there were 6 winners for our 1st Innovation & Productivity Award.

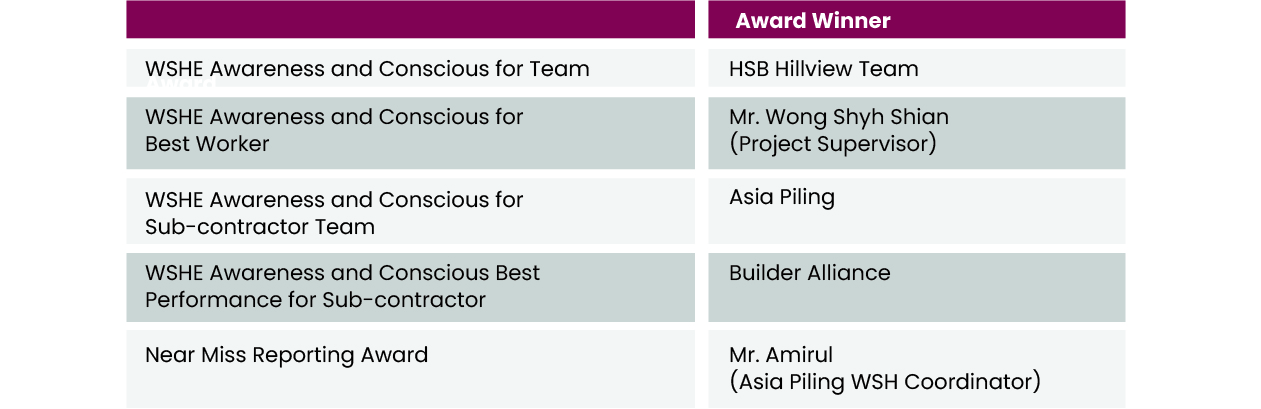

Their winning solutions were as follows:

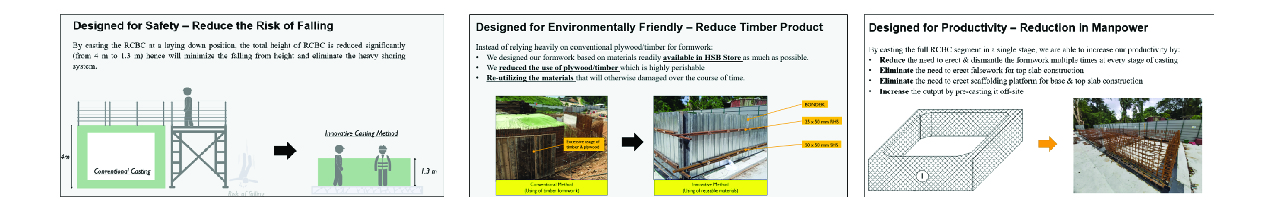

Precast RCBC Design by Project J113 – The project team explored alternative method to rework conventional cast-in situ RCBC construction to precast RCBC with the intention to:

From on the adoption of precast RCBC on site, the team managed to achieve an overall 42% increase in productivity as compared to conventional cast-in situ method and this proposal was supported with safety factor considerations and PE design.

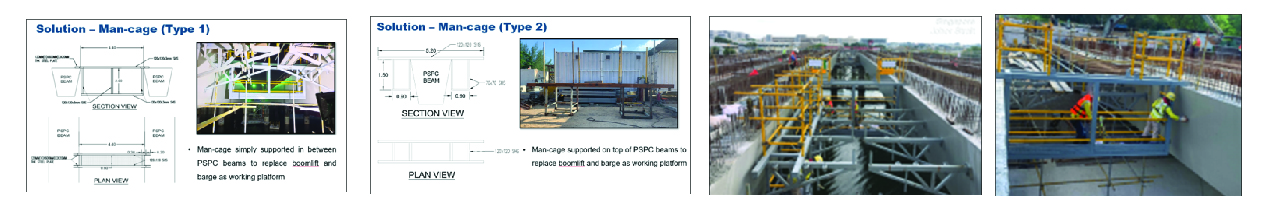

Cantilever Man Cage Design by T738 – The proposed Man-cage was simply supported in between PSPC beams to replace use of boom lift and barge as working platform. The man-cage concept which was accompanied with PE design, reuse materials such as hollow sections and steel plates for the fabrication. This innovative solution had helped the project team to reduced construction time and manpower with minimum machineries deployment as well as ensuring workers’ safety while working at height above waterway.

Precast Kerb Clip Design by Project DE113 – The group used damaged/ dented GI pipes and SHS on site to fabricate this precast kerb clip with the objective to prevent hand injury. Pinch point injuries to hands and fingers were significantly reduced after the implementation of the solution by the project team.

For Smart AI Recognition Concept by Design & Planning Department – New software development for Automated comparison of drawings and documents using AI capabilities which is able to achieve significant time/cost savings towards work completion and is applicable to be used by Engineers and Quantity Surveyors

Submission Tracking Platform by Mr Gao Shuyu (Senior Engineer) – Use of affordable Clickup Online Platform to track extensive clients correspondences, design coordination and authorities submissions in one single platform together with the consultants/ designers.

The project team has benefited substantial time saving when retrieving required project information as data are synchronized and all parties will get notification for any changes make to the drawings, documents etc. Abortive works will be greatly reduced on site.

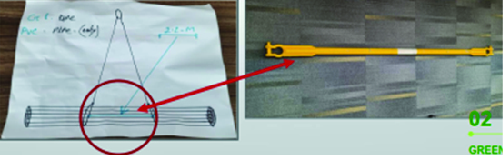

Lifting Catch Using GI Pipe by Mr Rabiul (Operator) – Using recycle GI pipe as a catch to prevent materials from sliding and dropped during lifting operation.

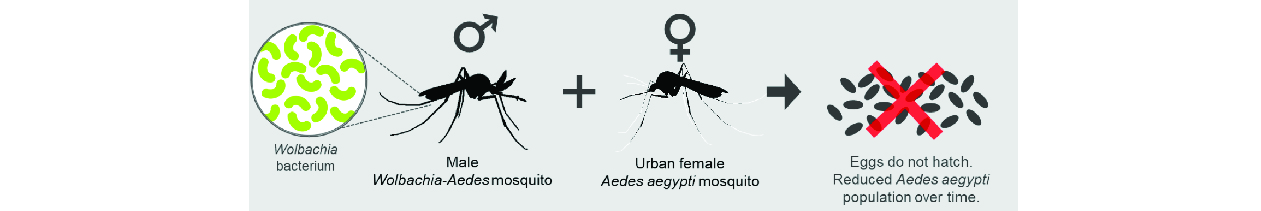

Wolbachia is a bacteria that occur naturally in 50% of insect species, and when Aedes Mosquitoes are found to be carrying Wolbachia, the bacteria compete with viruses like Dengue, Zika Chikungunya and yellow fever, hence making it harder for viruses to reproduce inside the mosquitoes. Through these findings, the World Mosquito Program would breed Wolbachia-carrying mosquitoes, and release them into areas affected by mosquito-borne diseases.

When the male Wolbachia-carrying Aedes mosquitoes mate with urban female Aedes mosquitoes that do not carry Wolbachia, their resulting eggs would not hatch. Over time, the continued release of the male Wolbachia-Aedes mosquitoes would lead to a decline in urban Aedes-mosquito population, hence reducing the risk of dengue and also other Aedes aegypti-borne diseases such as Zika and chikungunya. (source: worldmosquitoprogram.org)

Project Wolbachia Singapore was rolled out in year 2017, where the male Wolbachia-Aedes mosquitoes are released into our urban environment across 39 HDB blocks, covering 3,941 households. Till date, the male Wolbachia-Aedes mosquitoes have been released to 31% of all HDB blocks in Singapore, accounting to more than 300,000 households. This method has been proven to significantly suppress urban Aedes aegypti populations in Singapore.

1,258 dengue cases were reported in the week ending 18 June 2022, 208 cases fewer than in the previous week. The weekly number of dengue cases is expected to rise and will likely surpass the highest weekly figure of 1,787 cases seen in 2020.

The authorities have issued 59 stop-work orders to construction sites for repeated mosquito breeding offences this year. NEA urges all construction worksites to take urgent action to break disease transmission. We can do our part to fight dengue by removing stagnant water and potential mosquito breeding habitats by following the ‘B-O-L-D’ steps regularly:

Backfill uneven surfaces and remove ground puddles

Organise materials neatly to prevent water accumulation

Look for potential breeding grounds

Dispose unwanted materials and litter

The project team of DE113, celebrated the safety milestone of achieving 1 million Manhours Without Loss Time Injury on the 26th May 2022. The project which comprises of constructing commuters and road infrastructure at Hillview, Dairy Farm Road and Tuas Area, started works in November 2019. The HSB team had worked in collaboration with sub-contractors, and constantly advocated the importance of Safety and Health with the key message of having a clear and concise safety mindset.

This encouraged the teams to identify and report all Unsafe Acts and Unsafe Conditions to the supervisors and the safety teams that helped to eliminated the number of potential incidents on site. Safety timeout sessions and skills targeted trainings were carried out frequently as it serves as a constant reminder to do the work safely, and safety lies in their hands.

Left: Representative of SPF receiving token of appreciation from our Managing Director, Mr. Thomas Ng.

Right: Representative of Hilti receiving token of appreciation from our Managing Director, Mr. Thomas Ng, and Executive Director, Mr. Alan Nah.

Left: Representative of CSK Landscape Services receiving token of appreciation from our Managing Director, Mr. Thomas Ng, and Executive Director, Mr. Alan Nah.

Right: Representative of NEA receiving token of appreciation from our Deputy Director (Projects), Mr. Craig Kerr, together with DE113 ECO, Mr. Ramesh.

Governments agencies such as Singapore Police Force, National Environment Agency, NParks and MOM Ace as they did presentations on their field of expertise. This demonstrated the care and support from the government agencies and boosted the morale of the team.

Our guests were then presented with a token of appreciation from HSB Managing Director, Mr. Thomas, and Executive Director, Mr. Alan Nah, after the event.