WSHE BULLETIN

May 2022

Issue #53

Over the years, with the effort from everyone in HSB, we have received multiple awards and accolades. In 2021, we were awarded a total of 15 EHS related awards and recognition. Of the 15 awards, 2 awards highlighted HSB role in providing the support to individual and construction partner to excel in their EHS performance. The 2 awards are “WSH Officer Recognition Award”, awarded to Mr Azry Tay and “Subcontractor’s Safety Recognition Award” awarded to Bok Seng Logistics Pte Ltd. 2021 also saw HSB lands its first international award in the form of “ROSPA Gold Award”.

Starting on the correct foot, HSB garnered 3 awards in the recent Land Transport Excellence Awards (LTEA) 2022. The LTEA is a biennial event organised to recognise industry partners and individuals who have played a pivotal role in Singapore’s endeavour towards developing a people-centred, efficient, and sustainable land transport system. The Awards aim to showcase best industry practices in Singapore’s land transport system and has created positive brand equity for the land transport industry players, as they work together to enhance travel experience for all commuters.

Having progressed well in our operations, it takes a monumental effort from everyone within the organization to maintain and continuously improve such performance. Therefore, it is crucial to maintian our EHS culture. This would call for everyone to carry out and participate in the various EHS initiative diligently and constructively.

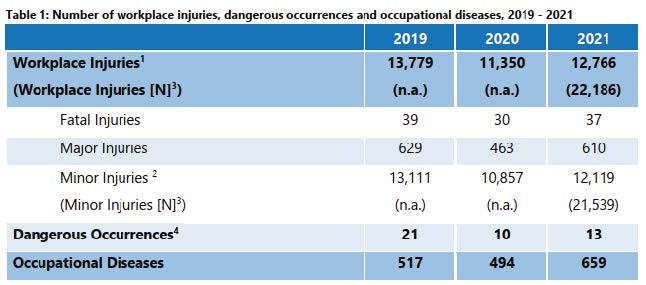

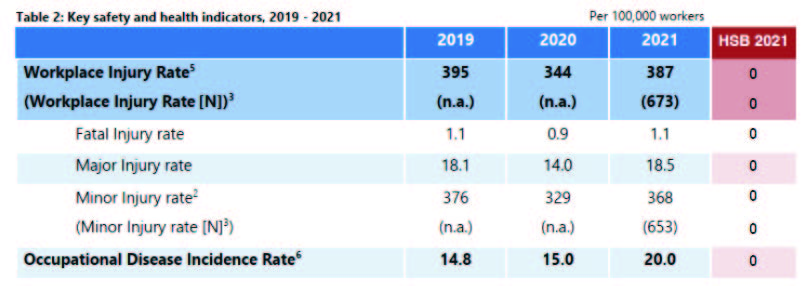

Further from the previous report released in the earlier highlights, the WSH Statistics has already taken into account the new provisions in the Work Injury Compensation Act (WICA) which took effect from 1 September 2020, in which employers need to report all work injuries with any instance of medical leave or light duties. Previously, reportable injuries pertain to those resulting in four or more days of medical leave or at least 24 hours of hospitalisation. With that there were 9,420 injuries with three or fewer days of medical leave or with light duties.

Main Findings on workplace injuries in the WSH Performance 2021:

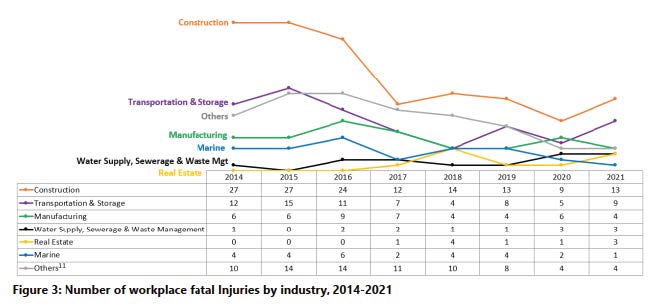

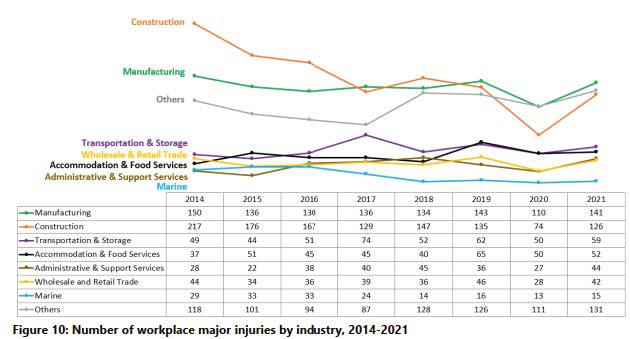

The construction industry remained the top contributor to fatal injuries (13). With regards to major injuries, the construction industry is the second top contributor to major injuries (126). From the report, it was also revealed that the top 3 causes for fatal injury were vehicular incidents, fall from height and fire & explosion. Vehicular incidents and fall from height made up 51% of the causes of fatal injury. Slips, Trips & Falls, Machinery Incidents and Falls from Height were the top 3 causes for major injury, making up 55% of all causes of major injury. Therefore, it is important that the EHS effort and the drive for continual EHS improvement, that HSB have put in, remain consistent.

The top management both at HQ and the various project sets the tone by making safety a top priority and providing resources to accomplish it. The commitment is also demonstrated by consistently being involved in safety programs and initiatives. Supervisors and managers lead by example. All personnel are equipped with sufficient knowledge to carry out their tasks.

HSB has developed a proactive system to identify and rectify hazards. It involves having the project team and the corporate team to work constructively and positively in a cycle of inspection. This cycle complements the routine inspections and safety activities carried out by the project team.

Responsibility and accountability in safety must be upheld by every personnel. No one is to feel vulnerable. Every personnel understands that there will be no negative consequences when reporting safety findings, near miss, suggesting safety improvement or even whistle blowing. Equality and respect also promote empowerment among personnel.

Connection between the organisation is kept strong. This s done through official publications, routine meeting, events and field inspection. A cohesive support system, through research and training, has also been establish to ensure that personnel are well equipped to implement the most updated requirements in the projects. This is coupled with ensuring that personnel are kept updated at all times.

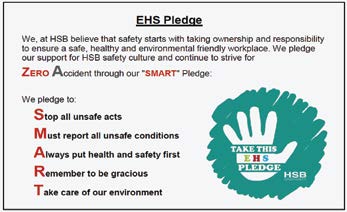

HSB has a very clear and simple safety policy within the Integrated Management System. To ensure that it is well accepted, we included a SMART pledge into it. This hasresulted to a comprehensive understanding of the policy and that it has become a principle in our EHS approach. We take this pledge every day.

HSB takes measurement from internal safety data, the direction of the industry and findings from external and internal audits. These continuous monitoring to identify gap and grow is key to sustaining the cycle of improving the organisation. With the numerous achievement and recognition, it spurs a lot of motivation, satisfaction, and drive among HSB personnel and strengthen teamwork.